| Sign In | Join Free | My chinacomputerparts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacomputerparts.com |

|

Brand Name : CRIDA

Place of Origin : Guangdong, China

MOQ : 1PC

Price : Negotiable

Payment Terms : L/C,D/A,D/P,T/T,Western Union,MoneyGram

Supply Ability : 100000Pcs/ Month

Delivery Time : 15-20 days

Packaging Details : As the requirement of customer

Model Number : Customized

Certification : ISO 9001:2015

Materials : Steel , Iron ,Stainless steel, Aluminum, Brass, Copper etc.

Process : Stamping, Deep drawing, Laser cutting,Bending

Drawing format : 3D/CAD/DWG/IGS/STP

Surface treatment : Zinc plating, Nickel plating, Powder coated , Painting

Size : Custom as per the drawing or sample

Thickness of material : 0.2-20mm

Tolerance : Generally +/-0.1mm

Surface finish : Galvanization, chrome plate, powder coating, anodizing, etc

Color : Customized

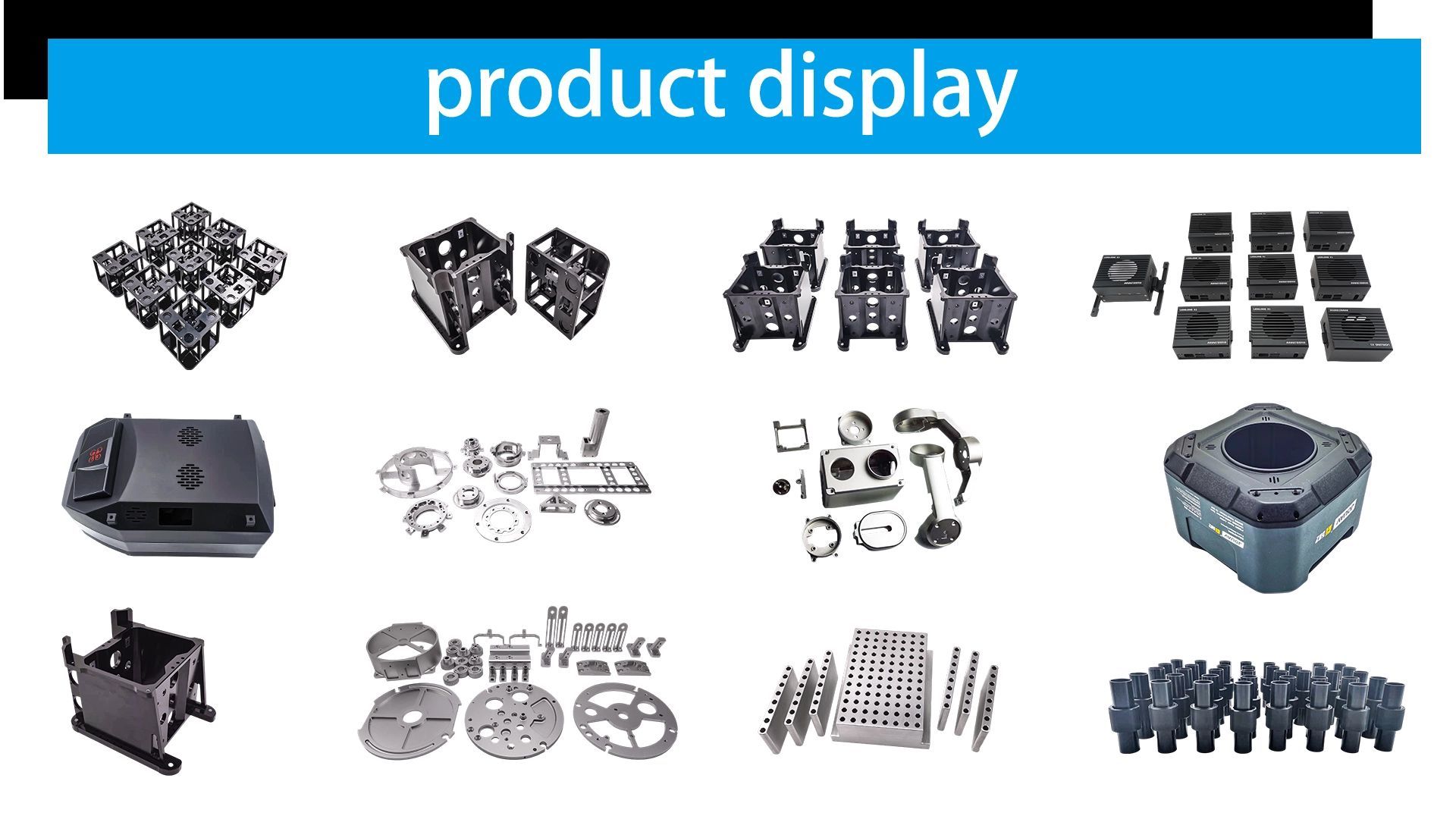

Highlight : Sheet Metal CNC Stamping Parts, Sheet Metal Stamping Sandblasting Stainless Steel Parts, Customized Precision Sheet Metal Stamping Parts Metal Bending Welding Fabrication

Stainless Steel Metal CNC Stamping Parts Powder Coated Metal Laser Cutting

Product Description

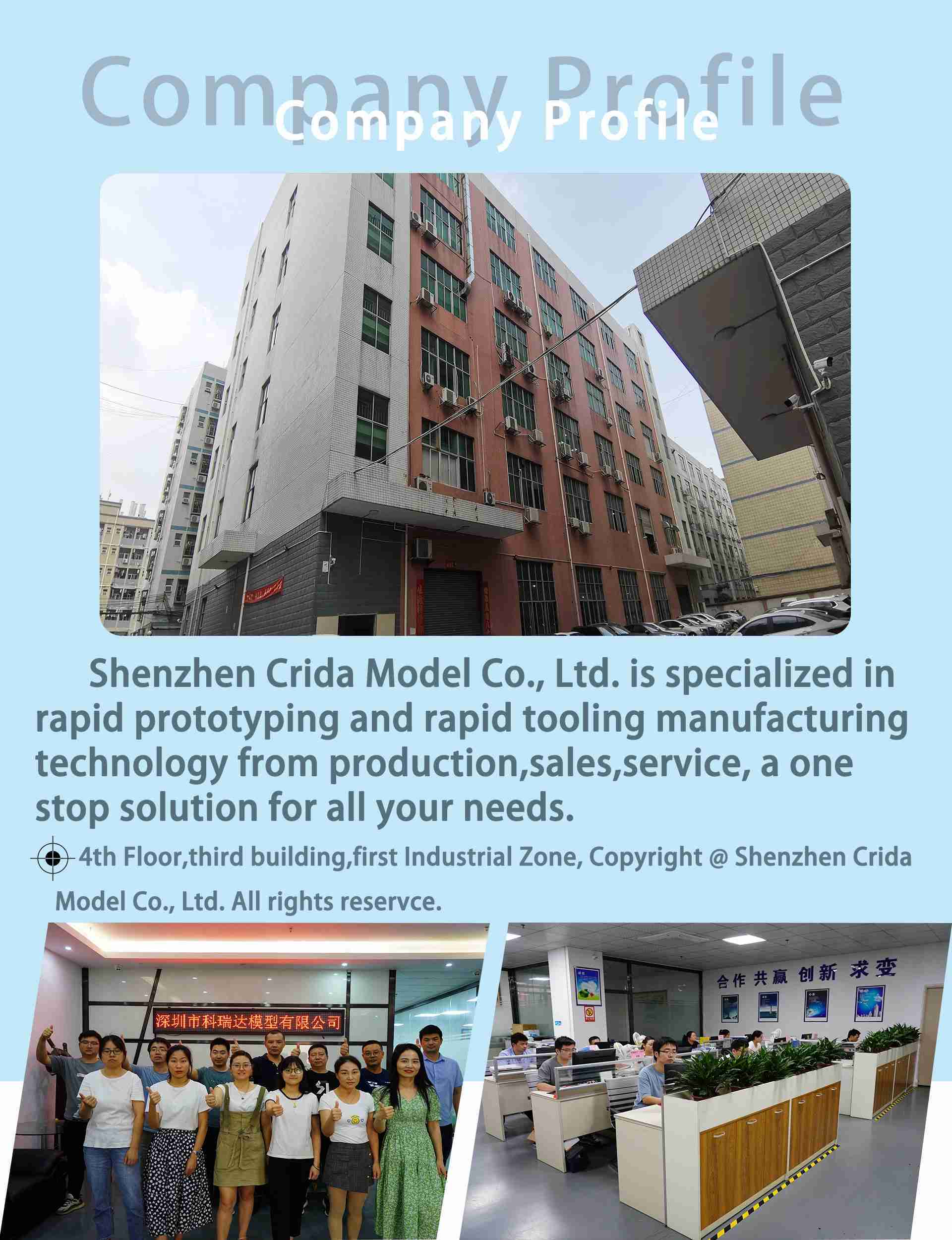

Crida stands as a premier provider of OEM Precision Sheet Metal Fabrication, delivering mission-critical solutions for the automotive, medical, motorcycle, and industrial sectors. Our advanced metal pressing and stamping processes achieve tolerances within ±0.1mm, ensuring consistent, repeatable results for complex geometries—from micro-medical components to structural motorcycle frames. Leveraging state-of-the-art equipment and certified materials (stainless steel, aluminum, specialty alloys), we combine high-accuracy stamping, CNC bending, and welding to transform raw sheets into durable, precision assemblies. We support both rapid prototyping and high-volume production, enabling seamless scalability without compromising quality.

Every project benefits from our experienced engineering team and end-to-end quality commitment. We deploy rigorous process inspections to ensure compliance with industry standards. Beyond technical excellence, we prioritize customer-centric collaboration: dedicated project managers provide real-time updates, DFM feedback to optimize designs, and flexible scheduling to meet urgent timelines. From automotive EV battery trays to surgical instrument housings, our solutions balance precision, durability, and cost efficiency. Trust Crida not just to meet specifications, but to redefine what’s possible in precision sheet metal fabrication.

Features

Technical Parameters

| Product Name | Custom Precision Sheet Metal Stamping Parts |

| Size | Accept custom size |

| Material | Carbon steel, SPCC, SGCC, Stainless steel, Aluminum, Brass, Copper, etc. |

| Processing | Laser Cutting, Precision Stamping, Bending, CNC Punching, Grind, Riveting, Drilling, Welding, etc |

| Surface Treatment | Brushing, Polishing, Anodizing, Powder Coating, Plating, Silkscreen printing, sandblasting, etc |

| Drawing Format | DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI, PDF, JPG, Draft. |

| Tolerances | ±0.1mm, 100% QC quality inspection before delivery, can provide quality inspection form |

| Color | White, blank, silver, red, grey, Pantone and RAL, etc |

| Specification | Customized |

| Price Term | EXW, FOB, CIF, DDP, DDU, etc |

| Payment term | Sample: 100% payment before production Mass production: (50% in advance as deposit, balance before delivery) |

Applications

Crida delivers ISO 9001:2015-certified precision sheet metal stamping with exceptional tolerances (0.01–0.05mm) for OEM applications. Our advanced metal pressing process ensures accuracy and consistency in fabricating complex components—from micro-electronics housings to structural automotive parts—while reducing costs and accelerating turnaround times. We serve critical sectors including automotive (sensor mounts, EV components), medical (Medical device enclosures), aerospace (avionic enclosures), and consumer goods (appliances, communication devices), leveraging cutting-edge technology to transform raw materials into high-performance solutions with uncompromised quality.

As an industry leader, Crida combines engineering expertise with state-of-the-art stamping tools to exceed stringent customer requirements. Our team delivers rapid prototyping to high-volume production with no minimum order quantity (MOQ=1), ensuring flexibility for urgent projects. Beyond precision, we prioritize cost efficiency through optimized workflows and competitive pricing. Whether producing marine hardware brackets or life-saving medical equipment, our end-to-end service guarantees reliability, speed, and technical excellence. Contact us today to engineer your next breakthrough with confidence.

Packaging & Shipping

All precision metal stamping parts are packaged in five-layer thickened corrugated boxes, and heavy parts are shipped in customized wooden boxes. Customized shock-proof pads and edge protectors are configured internally to ensure transportation safety. The packaging plan is specially designed according to the product protection level and logistics requirements. Delivery strictly follows customer instructions, and carriers use intelligent cost algorithms to optimize (DHL/UPS/sea transportation, etc.) to achieve a balance between cost performance and timeliness. Each batch of goods is insured for total loss, covering the risk of loss and damage, and is accompanied by a real-time logistics tracking system. From rust-proof treatment to destination signature, we use quality control that is higher than the industry standard (damage rate ≤ 0.02%) to ensure the safe and timely delivery of products.

|

|

Stainless Steel Metal CNC Stamping Parts , Powder Coated Metal Laser Cutting Parts Images |